PRODUCTS

Product Category

Roll Forming Machine

Item No.:

CZ-002

Category:

Summary

We offer a wide range of services including product and tool design, hot forging, casting, deep draw (cold extrusion), cold heading, high precision CNC machining, surface finishing, and sub-assembly. Our main products are high precision accessories of Power system, electrical and telecommunication industry,

keywords:

Description

Specification:

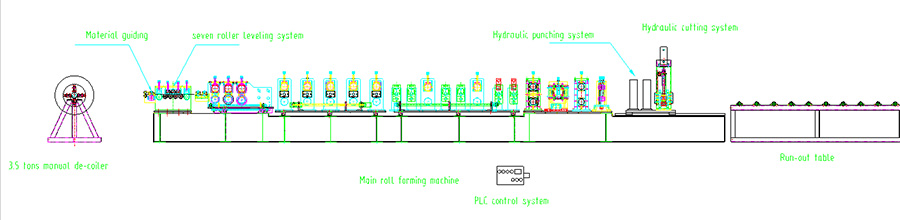

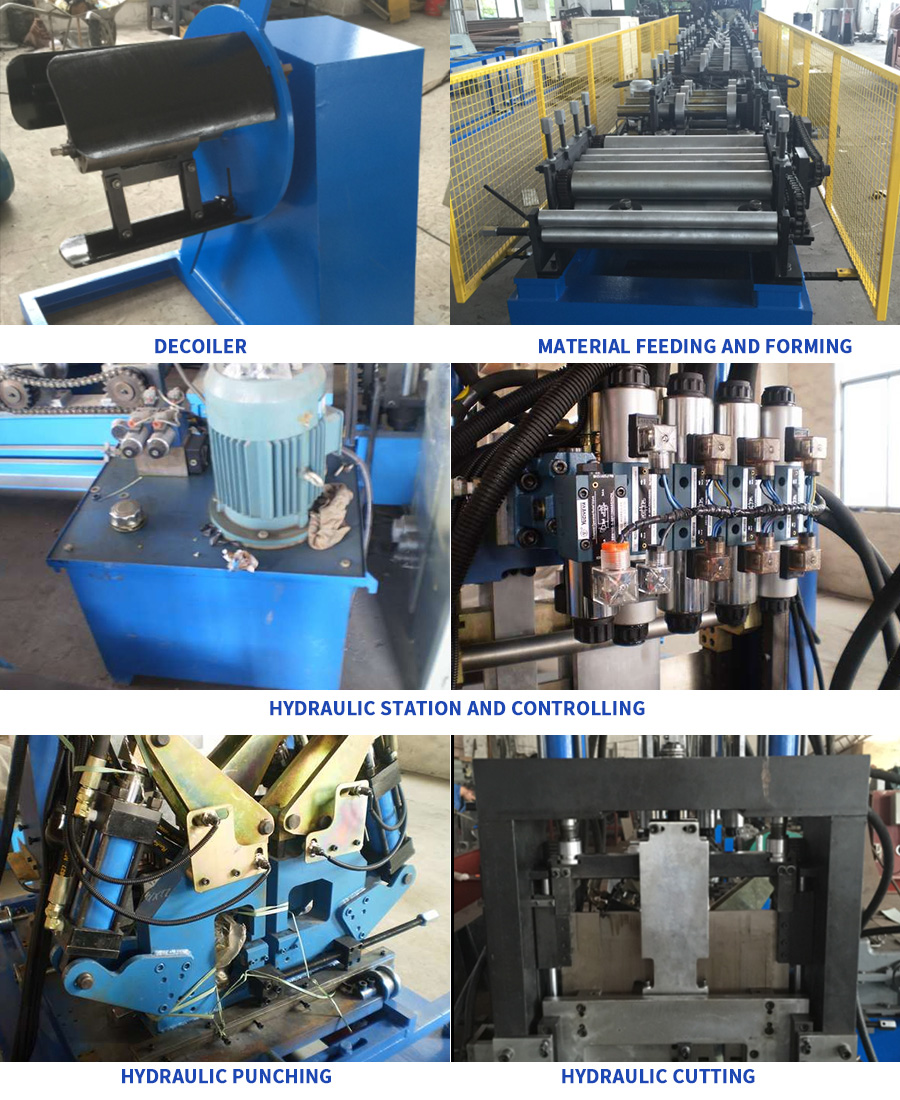

1. Main composition of the machine:

The machinery line consists of de-coiler with its base, feeding , material feeding and flatting , roll forming machine , hydraulic punching, PLC cut to length system , run out table, control cabinet with PLC.

2. Technical parameters:

|

1 |

Material thickness |

1.5-3.0mm |

|

2 |

Raw material |

Steel coil |

|

3 |

Yield Strength |

235Mpa |

|

4 |

Stations |

14 stations |

|

5 |

Material for the rollers |

Gcr15 steel with harden and chrome plate treatment, the surface of the rollers will be mirror polished |

|

6 |

Material for the station |

Support side plate(40mm) |

|

7 |

Shafts |

Diameter: 70mm material: Cr 40 with harden treatment. |

|

8 |

Line speed |

4-8m/min (including punching and cutting time) |

|

9 |

Main motor power |

15KW |

|

10 |

Punching method |

Hydraulic punching by PLC controlled |

|

11 |

Hydraulic station power |

5.5KW |

|

12 |

Voltage |

4150V/50HZ/3PH |

|

13 |

Way of control |

PLC cabinet |

|

14 |

Tolerance |

Total Length: 3m±1mm |

|

15 |

Type of transmission |

Most parts chain and some parts of gear |

|

16 |

Length of the line |

22m*1.8m*2m |

|

17 |

Container |

One 40 GP |

|

18 |

Spacer |

The spacers will be electroplating treatment |

|

19 |

Total power |

About 21KW |

3. Cutting and the control cabinet:

Cutting:

(1) Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start.

(2) Material of blade: CR12with heat treatment

(3) Length measuring: Automatic length measuring

(4) Tolerance of length: +/- 1.5mm

Control cabinet: Brand: Panasonic

(1) Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase (this is can depend on customer request)

(2) Automatic length measurement:

(3) Automatic quantity measurement

(4) Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved

(5) Length inaccuracy can be amended easily

(6). Control panel: Button-type switch and touch screen

(7) Unit of length: millimeter (switched on the control panel)

4. Working Flow:

De-coiling the sheet -coil strip feeding –material flatting---roll forming --- hydraulic punching---plc control cut to length system -panels to the collecting platform— Finish

5. Packing List details:

|

3.5 Tons manual de-coiler |

1 set |

|

Main roll forming machine |

1 set |

|

PLC Control cabinet |

1 set |

|

Hydraulic cutting |

1 set |

|

Hydraulic punching |

2 set |

|

Run-out table |

2 set |

|

Punching mould |

2 set |

6. Components:

|

Frequency changer |

Panasonic |

|

PLC |

Yaskawa |

|

Encoder |

Omron |

|

Other electrical |

Schneider |

Online Message

Thank you for your attention to us. If you have any needs or comments, please leave us a message.